The Challenge:

BJC Machine Tools, an Australian-owned company specialising in CNC machine sales, service, and support, has earned a solid reputation across the country. They offer a range of services from breakdown repairs to scheduled maintenance for businesses all around Australia. As their business expanded, managing inventory and operations became increasingly difficult, especially since their stock wasn’t only held in warehouses but also distributed across repair vans used by their technicians in the field.

The reliance on manual Excel spreadsheets for tracking inventory across their head office, warehouses, and repair vans was holding the company back. It was clear that a more efficient, real-time solution was needed to keep up with the growing demand.

Here were the key challenges BJC Machine Tools faced:

- No real-time visibility: Tracking stock across head office, warehouses, and repair vans manually through Excel was leading to frequent mistakes and miscommunication.

- Human errors: Multiple team members updated the same spreadsheets, leading to confusion and mistakes, with no way to track who made changes.

- Inconsistent reporting: Creating accurate stock reports was a slow, manual process that didn’t reflect real-time inventory levels, making it hard to make timely business decisions.

- Stock shortages: Without a clear view of inventory in their repair vans and warehouses, stock shortages occurred often, impacting their ability to meet client demands efficiently.

- Reduced productivity: The reliance on manual processes for inventory and bookings was slowing down operations, increasing workload, and reducing profitability.

The Big Questions:

- Are manual, error-prone systems slowing down your business operations?

- Are you struggling to track inventory across multiple locations, including repair vans and warehouses?

- Is generating reliable, real-time reports becoming a time-consuming task?

For BJC Machine Tools, these issues were creating operational bottlenecks that were preventing the company from scaling effectively.

The Solution:

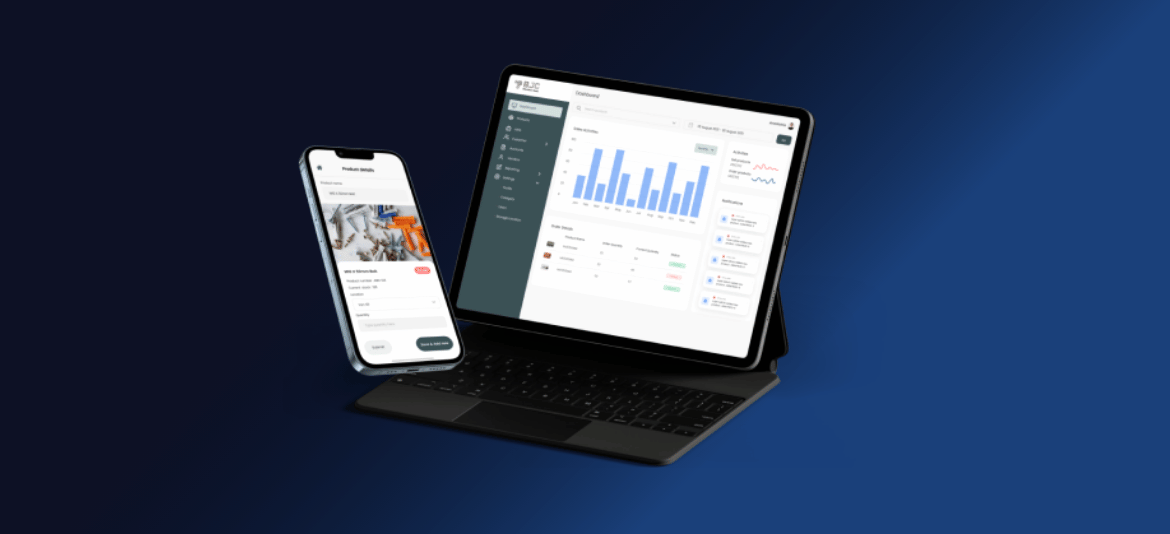

ISH Technologies worked closely with BJC Machine Tools to understand their specific workflow, including the challenge of managing stock not just in warehouses, but also in their fleet of repair vans. We developed a custom warehouse management system that provided real-time tracking and centralised control of their inventory.

Key features of the solution:

- Real-time stock tracking: The system provided real-time visibility into stock levels across head office, warehouses, and repair vans, allowing for easy monitoring and restocking.

- Automated alerts: The software automatically alerted managers when stock levels in any location fell below a threshold, ensuring they could restock quickly and avoid shortages.

- Warehouse barcode system: We integrated a warehouse barcode system, enabling fast, accurate tracking of inventory, both in warehouses and vans, streamlining the stocktake process.

- Easy-to-generate reports: The system automated reporting, providing real-time insights into inventory, making decision-making faster and more accurate.

The Result:

With their new custom warehouse inventory management software, BJC Machine Tools experienced significant improvements in efficiency and accuracy:

- Real-time control: The team now has a complete view of inventory across all locations—head office, warehouses, and repair vans—eliminating stock shortages.

- Reduced errors: The centralised system removed the guesswork and errors caused by multiple people updating manual spreadsheets.

- Faster reporting: Reports that once took hours to compile are now generated in minutes, giving management real-time insights into stock levels and movement.

- Increased productivity: With streamlined processes, the team is able to focus on delivering better service to their clients, improving overall business efficiency.

Thanks to their new warehouse management system, BJC Machine Tools has successfully transformed their operations, moving away from error-prone manual processes to a highly efficient, automated system that keeps their business running smoothly.